When it comes to describing the current supply chain climate, it is an understatement to say that it is characterized mostly by a scarcity of labor and suppliers rather than a lack of demand for goods and services.

A chronic lack of truck drivers existed prior to the COVID-19 epidemic, and the situation has now been exacerbated by a global labor shortage affecting a wide range of important professions, including dock workers and other warehouse workers.

People are staying at home in large numbers as a result of a combination of the virus, stricter public health precautions, and economic stimulus money. An increasing number of manufacturers and logistics companies are scrambling as a result of this circumstance, in order to ensure that their products are delivered in a timely way where they are needed.

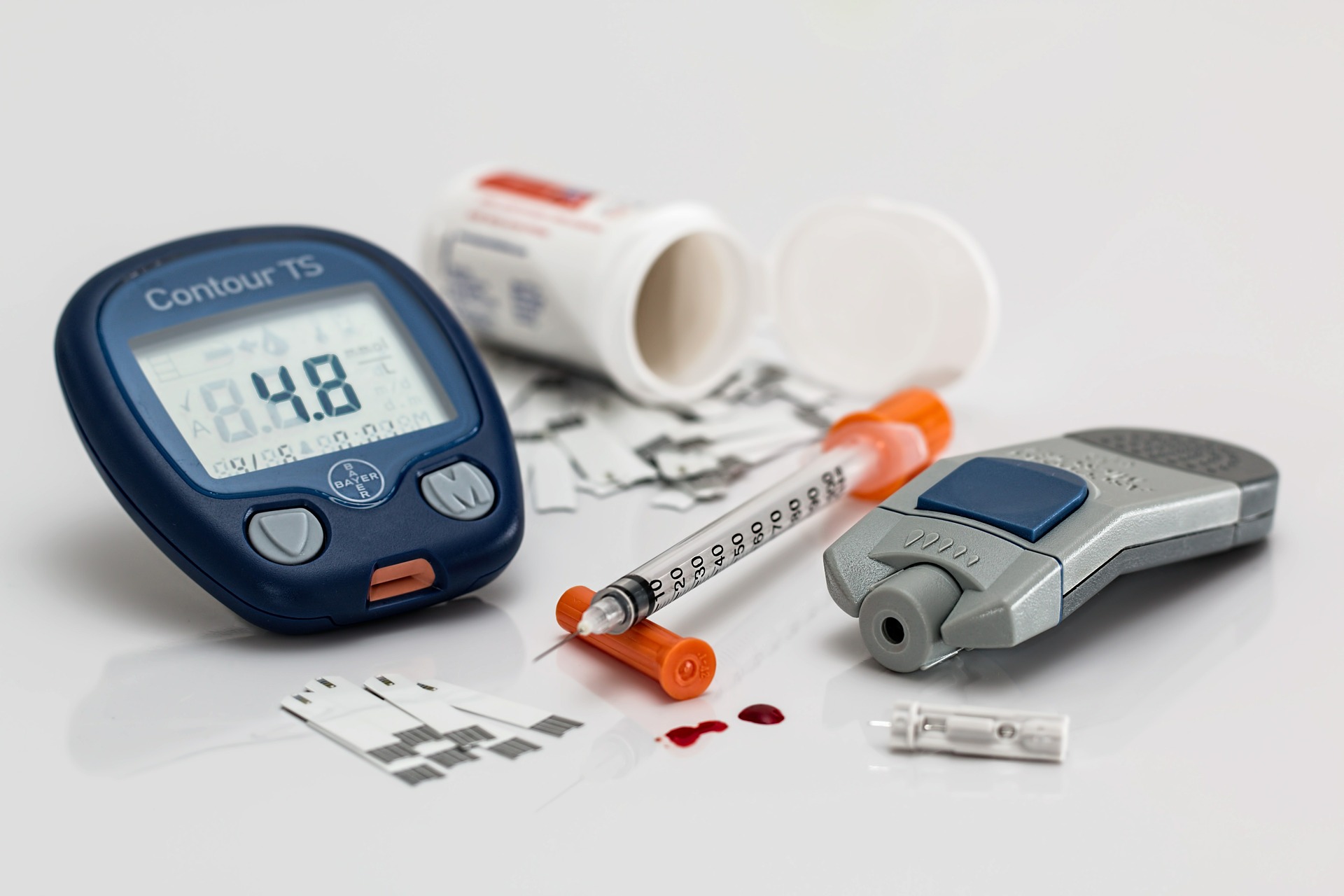

Suppose you are a project manager overseeing the replacement of a medical refrigerator in the fall of this year for a large pharmaceutical distribution company. Since the implementation of COVID-19, many pharmacies, including our client, have found themselves in the position of needing to expand their cold storage capacity to keep up with demand. They have therefore requested our support in organizing an effective swap-out at more than 3,000 locations across the country between now and the Thanksgiving break as their old equipment approaches the end of its functional lives.

In order to be successful, many elements, such as those involving sophisticated and heavy-weight equipment, must be taken into consideration. Multi-step logistics planning and execution must be implemented in order for these projects to be successful. It also serves as an illustration of some of the factors that manufacturers should bear in mind as they navigate the present supply chain environment. The following are some of the most significant things to keep in mind when making your decision.

Exactly what are the benefits of working with a single-source partner are?

A huge number of moving pieces is inherent in the structure of supply chains, and this has only become more complicated over the course of the preceding year. More than ever, collaborating with a single-source logistics provider who can handle your complete supply chain and use their contacts and relationships to aid them in lowering risk and enhancing efficiency is a good choice.

It is vital to put in a lot of effort into advance planning

When it comes to swap outs and upgrades in a single trip, pre-project planning is more critical than ever for manufacturers and their supply chain teams. This is especially true given the restricted number of workers available at this time.

After the initial trip to the site, a second trip is required due to the inability to remove and dispose of old systems while the new equipment is being delivered and installed on the site. Since qualified labor resources are in short supply, the number of events that may be held is severely limited.

Also required is for pre-planning teams to take into account and account for any unique logistical and delivery constraints that may arise at each location.

You should pay close attention to the finer nuances of the situation in order to succeed

Organizations must double-check that all of their “i’s” have been crossed and that all of their “t’s” have been crossed before initiating any swap out or rollout process. You will benefit from the execution of a well-thought-out supply chain plan because it will reduce errors and boost efficiency.

As a result, if you are disposing of obsolete products as part of a product swap out, you should take into consideration the nature of the materials handled by regulatory organizations in various industries, which may necessitate the requirement for evidence of destruction and specialized disposal techniques. A reputable partner will not only have the knowledge and experience necessary to ensure that these artifacts are disposed of in a proper manner, but they will also give thorough documentation of their procedures.

Furthermore, in order for all parties and stakeholders to be successful from the start, good top-to-bottom communication is required. Because of the pharmacy project, it was determined that our customer did not adequately explain the project’s importance to their local pharmacy personnel, as was the case with the previous pharmacy project. We had to start the deployment procedure several weeks later than we had originally intended in order to avoid further delays.

With a strong focus on localization, supply chain management is a reality

The ability to stage new goods locally in temporary, flexible pharmaceutical warehousing facilities could assist you in achieving new efficiencies, alleviating the consequences of current labor shortages, and lowering shipping costs. Read on to learn more.

When it comes to end-of-life items, working with a logistics provider who has local knowledge can save you money on the fees associated with returning electronics to the manufacturer, which can be significant. In the case of object disposal in the field rather of having them hauled back to headquarters for disposal, organizations can save as much as 33 percent on average, according to research.